Study focuses on fluidized bed design and the structure and performance of various kinds of oxygen carriers

Chemical looping fluidized bed reactors are an innovative technology for green hydrogen and chemical production. Recently, researchers have comprehensively reviewed the latest developments in chemical looping, with a focus on fluidized bed design and oxygen carrier performance. The findings of the study can pave the way for low-emission power generation, inherent carbon dioxide separation, carbon footprint reduction, and industrial decarbonization.

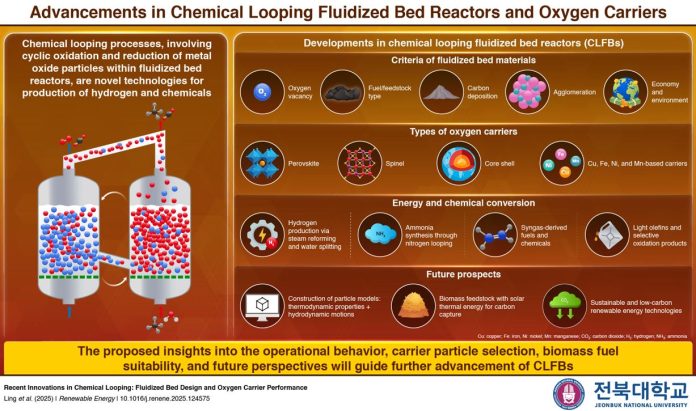

Traditional techniques of converting fossil fuels for heat and power generation and chemical production increase carbon footprint, harming society and environment. To mitigate this problem, carbon capture and storage technologies aimed at lowering carbon dioxide emissions and encompassing renewable energy utilization, circular economy, and green chemical synthesis are promising. Chemical looping is one such innovative technology. These processes—representing efficient technologies for hydrogen and chemical production applications—involve the cyclic oxidation and reduction of metal oxide particles in fluidized bed reactors.

In a recent study, a team of researchers led by Dr. Jester Lih Jie Ling, a post-doctoral researcher at Jeonbuk National University, has comprehensively reviewed the latest innovations in chemical looping. Their insightful findings were made available online on 7 October 2025 and have been published in Volume 256 of the journal Renewable Energy on 1 January 2026.

Dr. Ling highlights the major contributions of their work. “Our work highlights key advancements in fluidized-bed reactors that enhance reforming, gasification, and hydrogenation within chemical looping systems. It also emphasizes enhanced oxygen carrier materials with higher reactivity, durability, and resistance—critical attributes for long-term, stable operation.”

The researchers highlight various bed material criteria for both oxygen carriers and feedstocks in reactors, including oxygen vacancy, fuel/feedstock type, carbon deposition, agglomeration, and economical and environmental considerations. Importantly, the technological advancements in chemical looping in fluidized bed reactors enables the use of liquid and solid feedstocks, in addition to a wide variety of chemical pathways.

This review further suggests that the characteristics of oxygen carriers are significant from a microscopic perspective. They impact the yield and purity of the synthesized chemicals. Therefore, the synthesis method of the oxygen carriers plays a pivotal role in determining the overall performance of the process. Some representative methods include sol-gel, spray-drying, mechanical mixing, impregnation, co-precipitation, and freeze granulation techniques.

Considering the huge importance of oxygen carriers—such as perovskite, spinel, core shell, and Cu, Fe, Ni, and Mn-based barriers in chemical looping fluidized bed reactors, the team elaborates upon their structure and physical properties, as well as their performance during complex multiredox cycles. In this way, they contribute to the development of a physical standard for oxygen carriers in various energy and chemical conversion processes, including hydrogen production via steam reforming and water splitting, ammonia synthesis through nitrogen looping, syngas-derived fuels and chemicals, and light olefins and selective oxidation products.

Furthermore, the present work emphasizes the importance of controlling fluidization regime and constructing particle models that combine thermodynamic properties and hydrodynamic motions for yield optimization in chemical looping processes. It also

highlights the loss due to thermal and chemical reaction stresses as an area of interest for future research.

“The implementation of chemical looping processes in fluidized bed reactors is in alignment with the increasing demand for sustainable and low carbon renewable energy technologies, particularly when biomass is used as a feedstock with solar thermal energy for bioenergy carbon capture storage applications. Its benefits encompass low-emission power generation with inherent carbon dioxide separation, carbon footprint reduction in chemical production, particularly hydrogen, and industrial decarbonization. Overall, this review is expected to guide the further development of chemical looping fluidized bed reactors,” concludes Dr. Ling.